An Open Channel Flow Meter is a device used to measure the flow rate of water with a free surface, primarily applied in flow monitoring of non-full pipe flows or open channels such as rivers, irrigation canals, drainage networks, and sewage treatment plants.

The working principle is based on the weir and flume principles in hydraulics. The core method involves constructing a standard water-retaining or flow-contracting device of known dimensions in the open channel, such as a Parshall flume, triangular weir, or rectangular weir. When water flows through this device, it creates a backwater effect upstream, resulting in regular changes in flow patterns. By measuring the liquid level height at a specific location upstream of the device, the instantaneous flow rate can be calculated using the inherent level-flow relationship curve (or calculation formula) of that specific device. Therefore, open channel flow measurement is essentially a process of converting liquid level measurements to flow rate.

Common measuring devices are mainly classified into two categories: weirs and flumes. Weirs are barriers set in channels where water overflows the top, classified by notch shape as triangular weirs, rectangular weirs, etc. Flumes are sections of specific-shaped contractions, such as Parshall flumes and Sontek flumes, where water accelerates through. The choice of device depends on flow range, channel conditions, sediment content, and accuracy requirements.

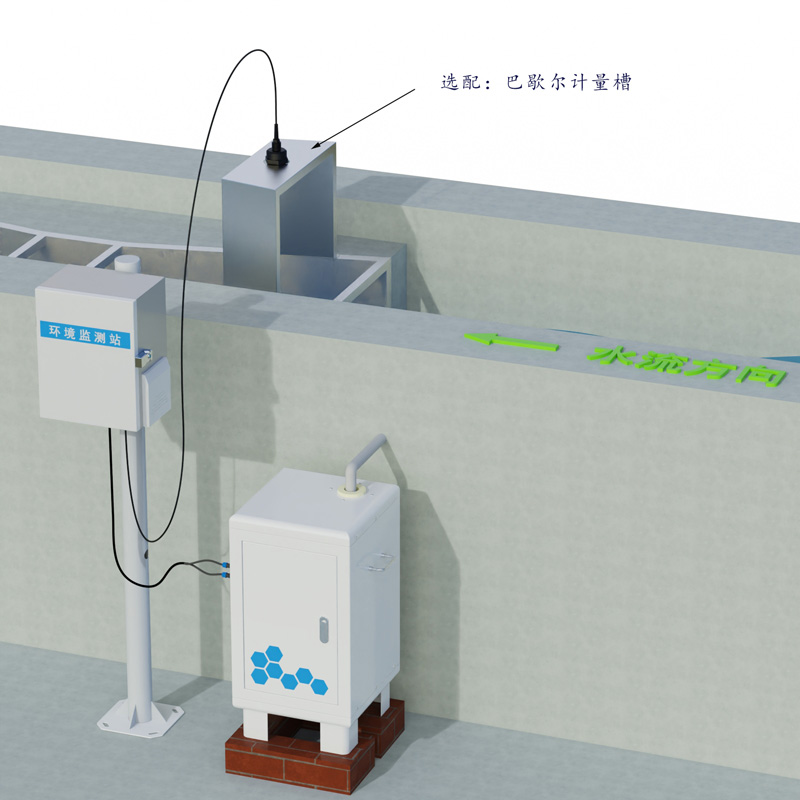

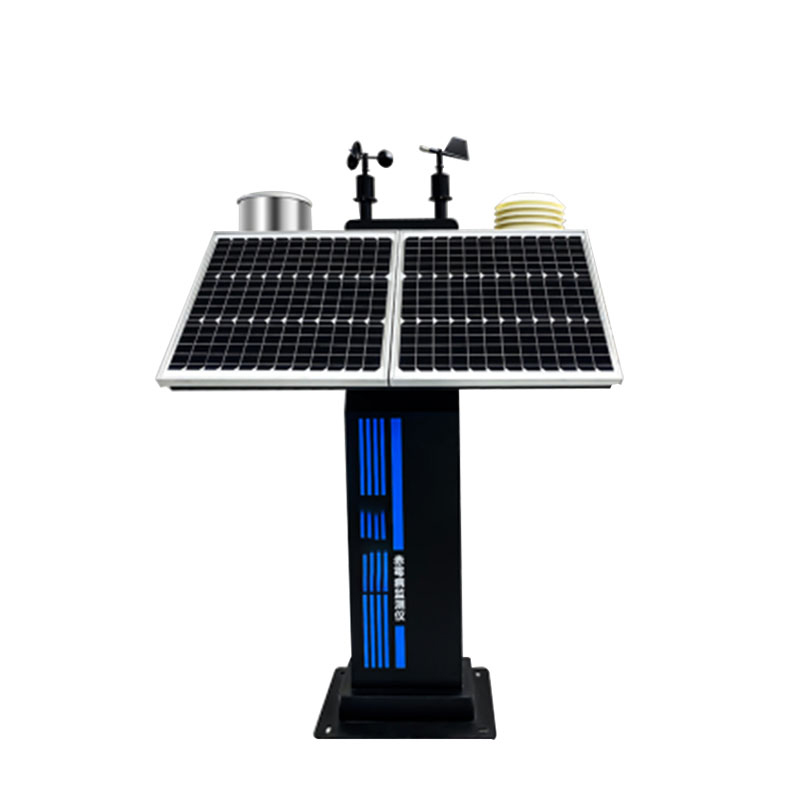

A typical measurement system consists of three parts: first, primary instruments (throttling devices) such as weirs or flumes that regulate the water flow; second, level measurement instruments (such as ultrasonic level meters, pressure-type level meters) that accurately detect the upstream liquid level; and third, flow integrators (secondary instruments) that store mathematical models of the selected weir or flume, receive level signals, and automatically calculate real-time and cumulative flow rates.

The advantages of Open Channel Flow Meters include relatively simple structure, high reliability, and resistance to clogging. The key points are that the manufacture and installation of weirs and flumes must strictly meet standards, and level measurement must be accurate, otherwise the accuracy of the final flow results will be directly affected. They are widely used in water metering and scheduling management in water conservancy, environmental protection, municipal engineering, and other fields.

This paper addresses:https://www.fengtusz.com/industry/848.html