Dams, as vital water conservancy infrastructure, undertake the tasks of flood control, irrigation, and power generation. However, the seepage problem in dams constantly threatens their safety and stability.

Seepage can cause soil and rocks inside the dam to gradually form cavities or channels under long-term erosion by water flow, a phenomenon commonly known as piping. The occurrence of piping greatly weakens the bearing capacity of the dam, and in severe cases, may even trigger local or overall collapse, leading to serious safety accidents and incalculable losses to the lives and property of people downstream. Additionally, the continuous increase in seepage pressure disrupts the internal stress balance of the dam, causing uneven stress distribution, further exacerbating dam deformation, promoting crack development, and ultimately potentially leading to structural damage. According to relevant engineering accident statistics, accidents caused by seepage account for 30%-40% of all accidents, second only to overtopping by floods. Therefore, precise monitoring and effective prevention of dam seepage are essential.

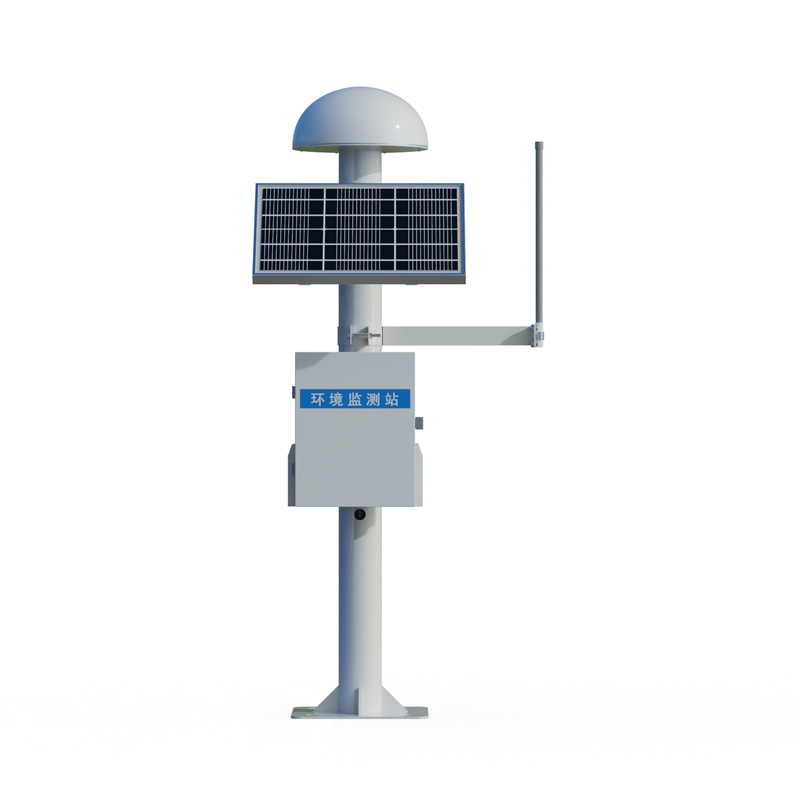

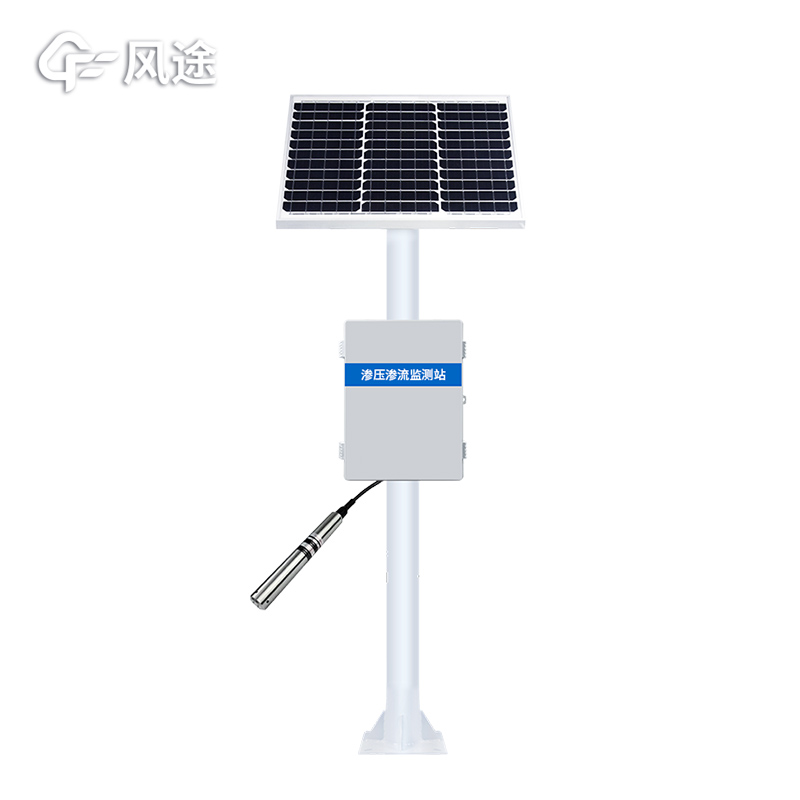

The weir gauge is an excellent tool for monitoring dam seepage, using a magnetostrictive sensor for liquid level measurement. This sensor boasts advantages such as high resolution, good stability, reliable performance, fast response speed, linear measurement mode, and no wear.

During operation, the weir gauge measures the water head over the weir, and then calculates the flow rate based on the empirical formulas of weir grooves (such as triangular weirs, trapezoidal weirs, rectangular weirs, etc.). Its specific structure includes a magnetic rod, float ball, measurement circuit, and stainless steel protective cylinder. When the water level in the weir groove changes, it drives the float ball to generate a liquid level difference. The upper computer obtains the actual water level over the weir by subtracting the calibrated base value from the current liquid level, and then calculates the flow rate according to the weir groove type. Through these precise data, managers can promptly and comprehensively grasp the seepage status of the dam and make scientific and rational maintenance and management decisions.

This paper addresses:https://www.fengtusz.com/industry/786.html