Dams are vital facilities for ensuring the rational allocation of water resources, flood control and disaster reduction, and hydropower generation. Maintaining their safety is of paramount importance. Therefore, it is necessary to design displacement monitoring for earth-rock dams and realize automatic monitoring, which helps to detect potential risks in a timely manner and ensure dam safety.

Firstly, the layout of monitoring stations in China must strictly comply with the Technical Specifications for Safety Monitoring of Earth-Rock Dams (SL551-2012). Surface deformation monitoring points are arranged in cross-sections, divided into monitoring transverse sections perpendicular to the dam axis and monitoring longitudinal sections parallel to the dam axis. Monitoring transverse sections should be selected at locations such as the maximum dam height or original riverbed, closure sections, terrain mutation points, areas with complex geological conditions, and positions with buried pipes in the dam or potential abnormalities. The number is generally not less than 3; monitoring longitudinal sections are generally not less than 4, and are arranged as specified on both upstream and downstream sides of the dam crest, above the normal water level of the upstream dam slope, and at different heights of the downstream dam slope. The spacing of monitoring transverse sections is determined according to the length of the dam axis: when the length of the dam axis is less than 300 meters, it is 20-50 meters; when it is more than 300 meters, it is 50-100 meters. Reference points should be set in areas outside the influence of the project, such as the abutments on both sides of the earth-rock dam or downstream areas with good geological conditions, with a number of not less than 3; working reference points are selected near the project area with relatively stable foundations, and their quantity and distribution meet the monitoring control requirements.

Dam displacement monitoring mainly includes two methods: manual observation and automatic monitoring. Manual observation focuses on overall stability, establishing a deformation monitoring control network unified with the coordinate system of the construction control network. Reference points are set in geologically stable locations, forming a monitoring network with working reference points and deformation observation points, generally monitored by total stations. Automatic monitoring involves establishing GNSS monitoring stations for key parts. To improve efficiency and accuracy, the two methods are integrated to form a Surface displacement monitoring system.

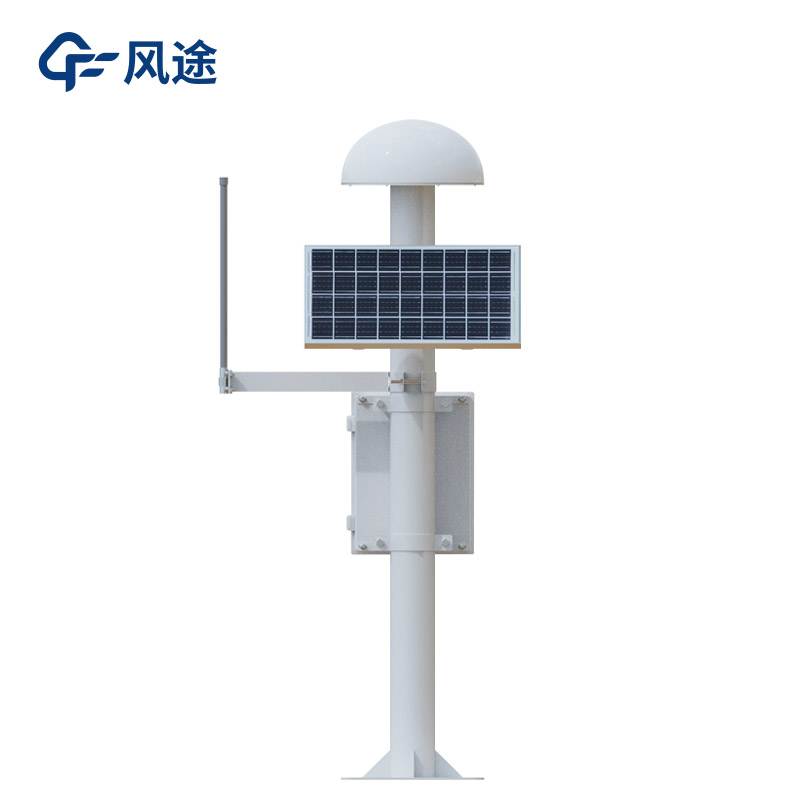

Monitoring station equipment includes a solar power supply system, storage battery, antenna, GNSS receiver, 4G data transmission terminal, charge-discharge controller, and integrated mounting bracket. These devices are integrated to provide hardware support for the collection and transmission of monitoring data.

The automatic monitoring system adopts a distributed, multi-level connected, and open network structure, set up at two levels: on-site monitoring stations and monitoring center stations. The on-site monitoring station consists of automatic monitoring instruments, data automatic acquisition units, and monitoring hosts. The acquisition unit collects data according to procedures, sends it to the monitoring center station after A/D conversion and storage, and receives control instructions from the center station at the same time. The monitoring center station centrally manages various data and related documents through the safety monitoring information management system, analyzes and releases monitoring data with the help of the safety analysis and evaluation system, and feeds back control instructions to the on-site acquisition computer.

Considering the outdoor environment of the dam, 4G communication network is preferred; in areas without 4G conditions, Beidou or other satellite transmission is used for data transmission. The power supply method usually adopts municipal power supply, or a combination of solar energy and storage battery to ensure the continuous and stable operation of the monitoring system.

Through the above design, the Surface displacement monitoring system can effectively monitor and early warn the displacement of earth-rock dams, ensuring dam safety.

This paper addresses:https://www.fengtusz.com/industry/790.html