The Automatic Soil Monitoring System used in planting areas consists essentially of automatic soil monitoring stations and a central data platform, providing critical data support for crop production.

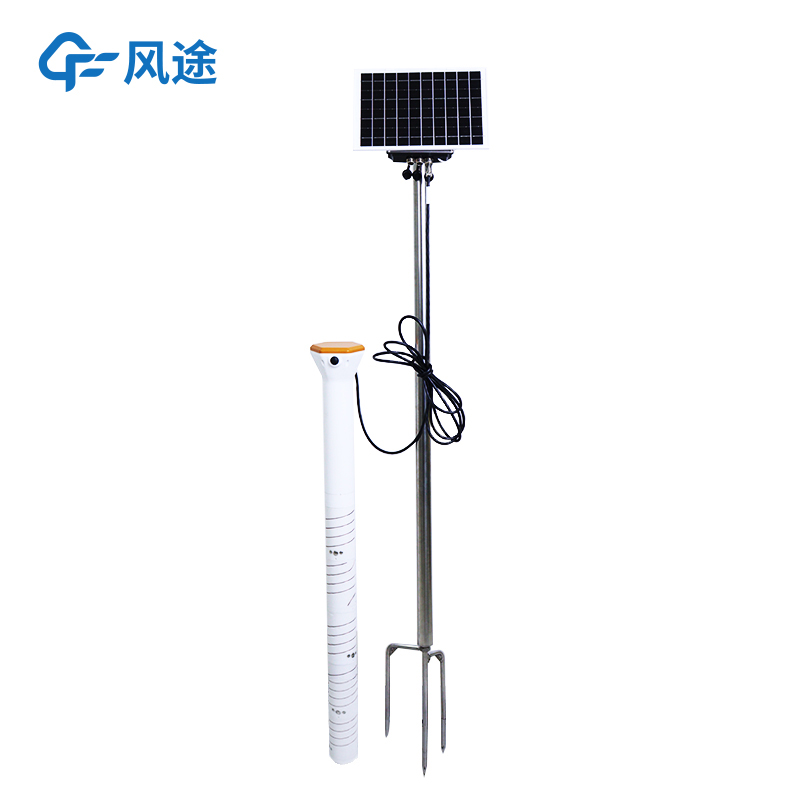

The automatic soil monitoring station serves as the core of the system’s front-end data collection. It can automatically, continuously, and accurately measure soil temperature and moisture content in crop production areas. This monitoring station features strong compatibility and can be adapted to various sensors closely related to soil moisture conditions, including soil water potential sensors, evaporation sensors, and electrical conductivity sensors. With the cooperation of these sensors, comprehensive soil-related parameters can be collected, offering real-time dynamic data support for irrigation decision-making in crop production. This helps growers accurately grasp the timing and amount of irrigation, preventing adverse impacts on crop growth caused by water waste or insufficient irrigation.

Relying on Internet functionality, the automatic soil monitoring station stably and promptly transmits monitored data—such as soil temperature, moisture content, and data collected by other sensors—to the central data platform via GPRS. Staff can intuitively view and analyze this data through the central data platform, enabling remote real-time monitoring of soil moisture conditions in planting areas.

The soil moisture sensors equipped with the monitoring station are capable of long-term field operation. They are directly buried at designated measurement points in open-field farmlands to conduct uninterrupted and continuous monitoring of soil moisture at different depths, ensuring the continuity and integrity of the collected data. The main unit of the monitoring station needs to be installed at a fixed location, while the moisture sensors and sensor data transmission nodes can be deployed flexibly. Staff can select appropriate locations around the main unit for deployment according to actual monitoring needs, greatly enhancing the system’s adaptability and convenience in different planting scenarios.

This paper addresses:https://www.fengtusz.com/industry/835.html